ON-SITE NITROGEN GENERATION

Let’s compare the main differences and advantages of these two most accessible on-site nitrogen generation technologies.

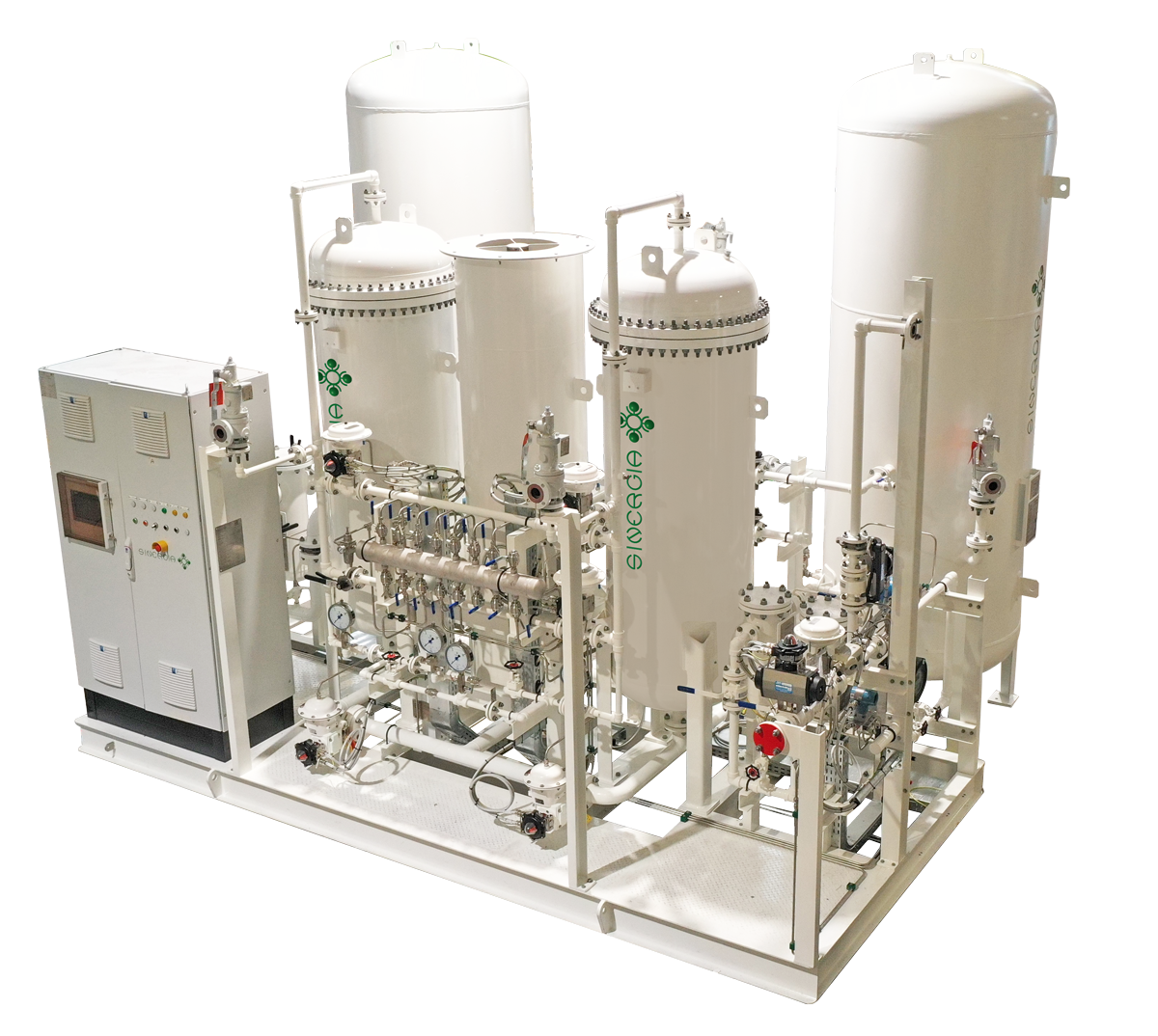

PSA (Pressure Swing Adsorption) technology

This technology enables the concentration of nitrogen from ambient air, typically from 78% up to 99.99%. The process involves compressing and treating the air—filtering impurities, dehumidifying, and possibly conditioning thermally—followed by cyclic passage through activated carbon beds. These beds selectively trap nitrogen molecules within their porous structure and release them in subsequent cycles, resulting in a concentrated nitrogen flow. The cycle is managed by alternating between two tanks to ensure a continuous supply of high-purity nitrogen.

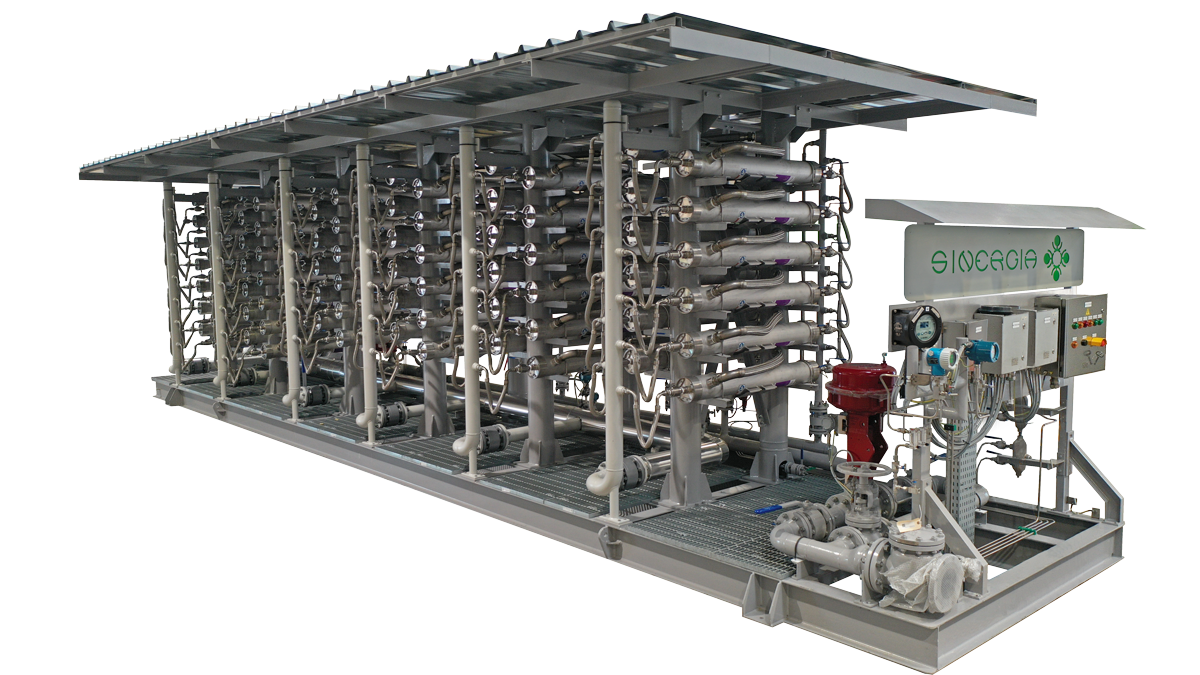

Membrane technology

This involves polymer hollow fibers with a porous structure designed to retain nitrogen molecules while allowing smaller molecules, primarily O₂, to pass through the fiber walls. As a result, nitrogen at up to 99.5% purity (and up to 99.9% for some manufacturers) is collected at one end of the fiber, while other gases are expelled through the membrane walls.

WHAT ARE THE KEY CRITERIA IN SELECTING THE PROCESS?

- Purity (Nitrogen Concentration):

Purity is the primary selection factor. Since energy costs for nitrogen production increase with higher purity levels, this parameter should align with actual operational needs. For example, for inerting purposes, a purity above 98% may not significantly reduce explosion risks. Higher purities might be necessary for other applications. Ideally, for purities above 99.9%, PSA or cryogenic technology (for large capacities and liquid nitrogen production) should be considered. For purity ranges between 96% and 99.5%, membrane technology is generally preferred due to simpler construction and maintenance. However, as purity requirements approach 99% or higher, membrane energy consumption increases exponentially, making PSA more advantageous. - Energy Efficiency:

Energy consumption is a critical factor, especially considering operational expenses (OPEX). The choice of technology impacts energy costs significantly, and selecting a more efficient system can justify investment costs over the plant’s operational lifetime. - Maintenance Costs:

Technological differences influence maintenance approaches. Membrane systems typically offer easier access for maintenance—components are generally accessible, lightweight, and manageable manually. They lack high-cycle valves, and membrane replacement is straightforward and clean. In contrast, PSA systems involve more complex components like activated carbon beds, which require careful handling during replacement to avoid damage or contamination. - Chemical Sensitivity:

Membranes are highly sensitive to hydrocarbons and ozone contamination, which can irreversibly damage the polymer fibers and rapidly reduce performance. Therefore, special attention must be given by generator manufacturer to controlling these contaminants in the feed air stream. - Operational Conditions and Environmental Factors: PSA units perform better at lower temperatures (around 35-40°C) and are suitable for moderate climates, operating generally at lower pressures. Membrane systems tend to be more efficient at moderate to higher temperatures (up to 60°C) and are preferable in hot environments.

CONCLUSION:

The optimal technology choice depends on a comprehensive evaluation of technical requirements, environmental conditions, energy sustainability goals, and the operational team’s expertise. The decision is often a mix of technical considerations and subjective factors, making each selection unique.

By leveraging experience, SINERGIA S.p.A. can assist in estimating CAPEX and OPEX, helping to identify strategies to mitigate specific installation and operational challenges, and facilitate an informed decision between PSA and membrane solutions.