Automation

The integration of our equipment or packages in existing plants or new greater projects, with relative requirements, has emerged the need of a specific answer.

Sinergia has decided to develop internally a dedicated department that is in charge of the engineering, manufacturing, assembling, testing, commissioning of:

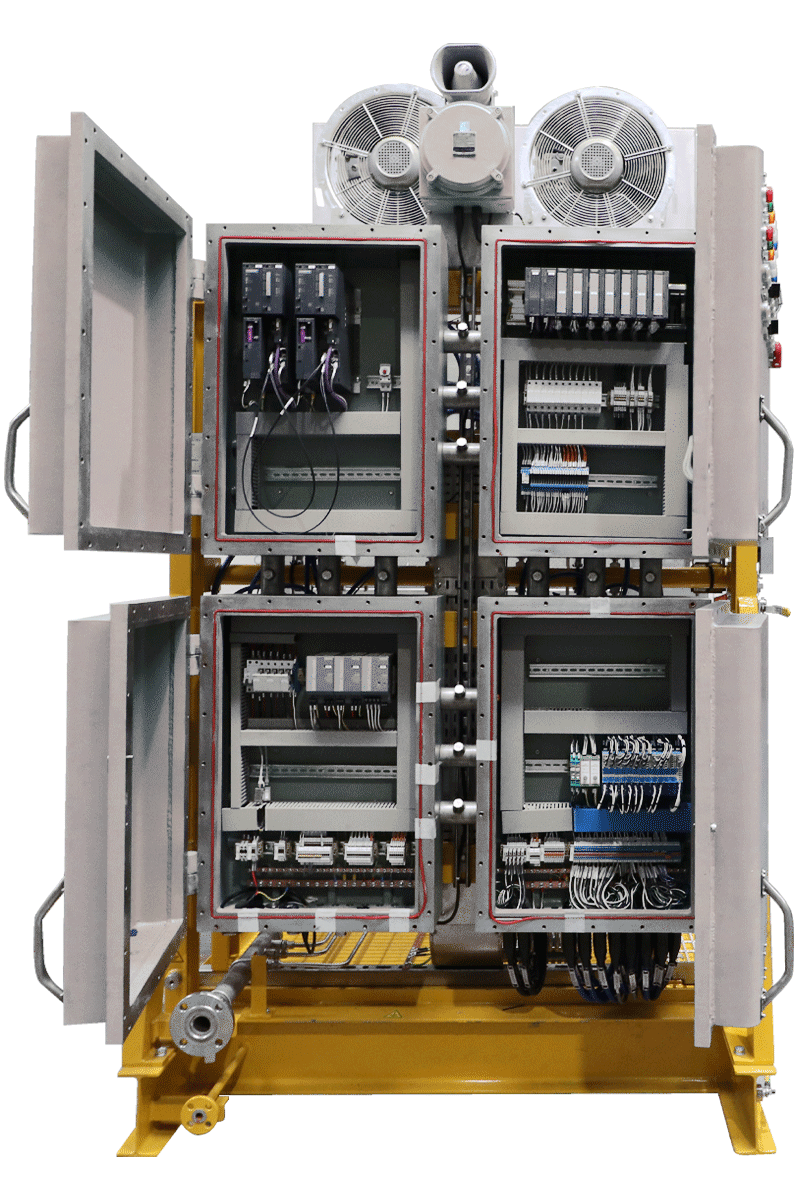

Electrical panels, junction boxes and push-button stations, having following features:

- Carbon or stainless steel, aluminium, GRP.

- Suitable for any ambient installation (-42°C/ +55°C) with variable heating or cooling solutions

- Suitable for any area classification Zone, 1, 2; certification as per Atex or IecEx

- Panel boxes Ex-d; Ex-e; Ex-ec; Ex-p; CE; Itri certified;

Unit control & Master control panels with the following features:

- Siemens and Rockwell (Allen Bradley) PLCs in the single or redundant configuration of CPU and I/O.

- PLC software and circuits with safety SIL loop

- HMI and SCADA Siemens; Movicon Rockwell

- Field bus: Profibus, ProfiNET, Modbus, Canbus, Hart, Fieldbus Foundation

Installation and testing of all electrical cabling and signal wiring

Files production accordingly with project document list:

P&ID, Load list, Control narrative, I/O list, Cause & effect diagram, Alarm & Trip list, Wiring diagram with GA and bill of materials, Loop diagrams.

Construction codes: 2006/42/CE; 2014/35/UE; IEC / CEI EN 60204-1 (2018); IEC / CEI EN 61439; IEC / CEI EN 60079-14; IEC 61508 and IEC61511

Blog

View all

our articles

The strength of an in-house manufactured PPU for Cryogenic Process

September 2024

The importance of an in-house pre purification unit in a Cryogenic Process

ADIPEC 2024 is coming closer

September 2024

Sinergia Stand: 11440 – Hall 11

N2 ARTIFICIAL LIFT vs ESP: Maintenance issues

August 2024

The N2 artificial lift system developed by Sinergia is not only a potential substitute for other artificial lift technologies but can be a very flexible and reliable alley (efficiency is 99% under 3 years of continuous operation) of those already installed.

PSA NITROGEN GENERATOR an efficiency improvement is possible… if you have all the skills

July 2024

Sinergia S.p.A., the leading Italian company in the engineering and manufacturing of nitrogen generators, has developed units suitable for continuous operation 24/24 h/d – 360/365 dd/y, in high ambient temperatures up to 55°C for upstream applications.

Sinergia receives the SA8000:2014 certification!

June 2024

Sinergia one of the 4000 world companies SA8000 certified.