Air Dryers

All units are fully packaged, including the in-house developed unit control system and can be supplied in variable configurations:

Sinergia standard design, or upgraded and engineered for heavy-duty and severe ambient installation, dangerous or explosive environmental conditions.

Air dryers are installed downstream the air compression in order to ensure the level of humidity content suitable for the process scope. Sinergia engineers and manufactures a wide range of membrane, refrigeration, and adsorption air dryers suitable for any kind of application and operating condition. Thanks to its flexibility Sinergia is capable to offer alternative technologies, selecting them in terms of efficiency and energy-saving. For each technology can be supplied standard, improved or completely engineered version, in order to satisfy all market requests.

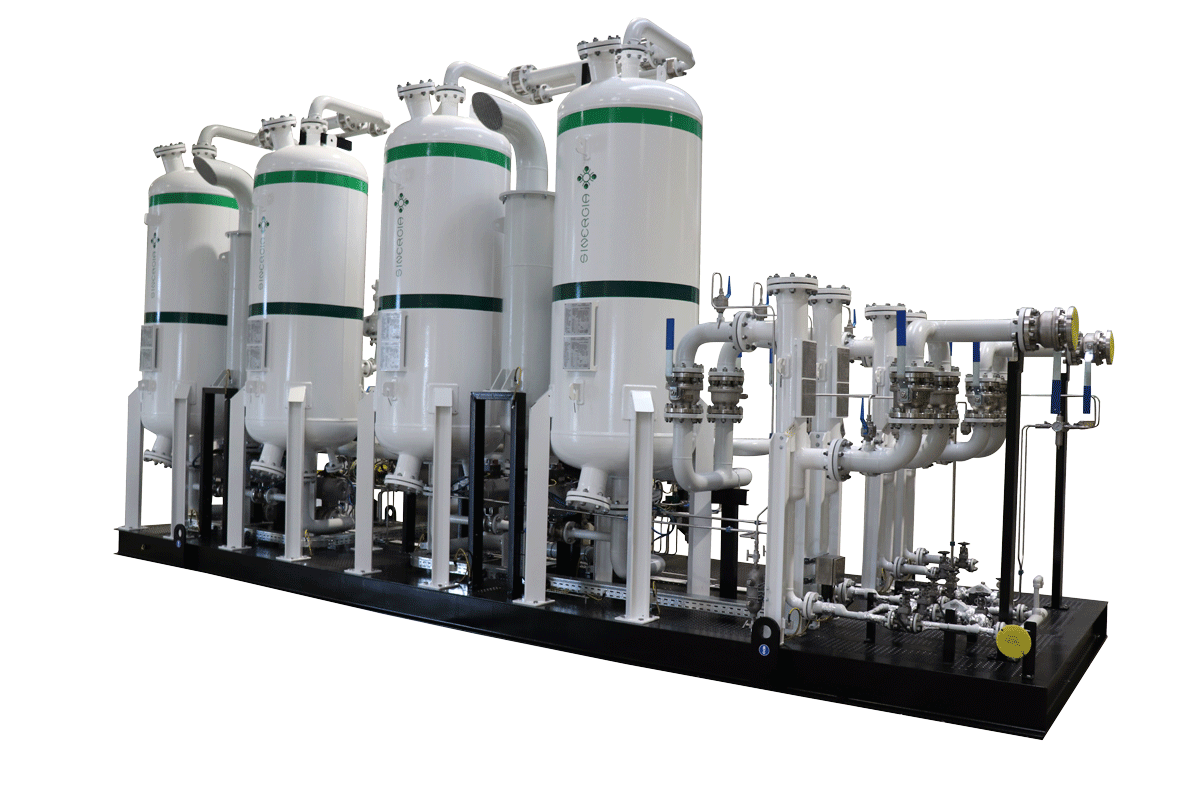

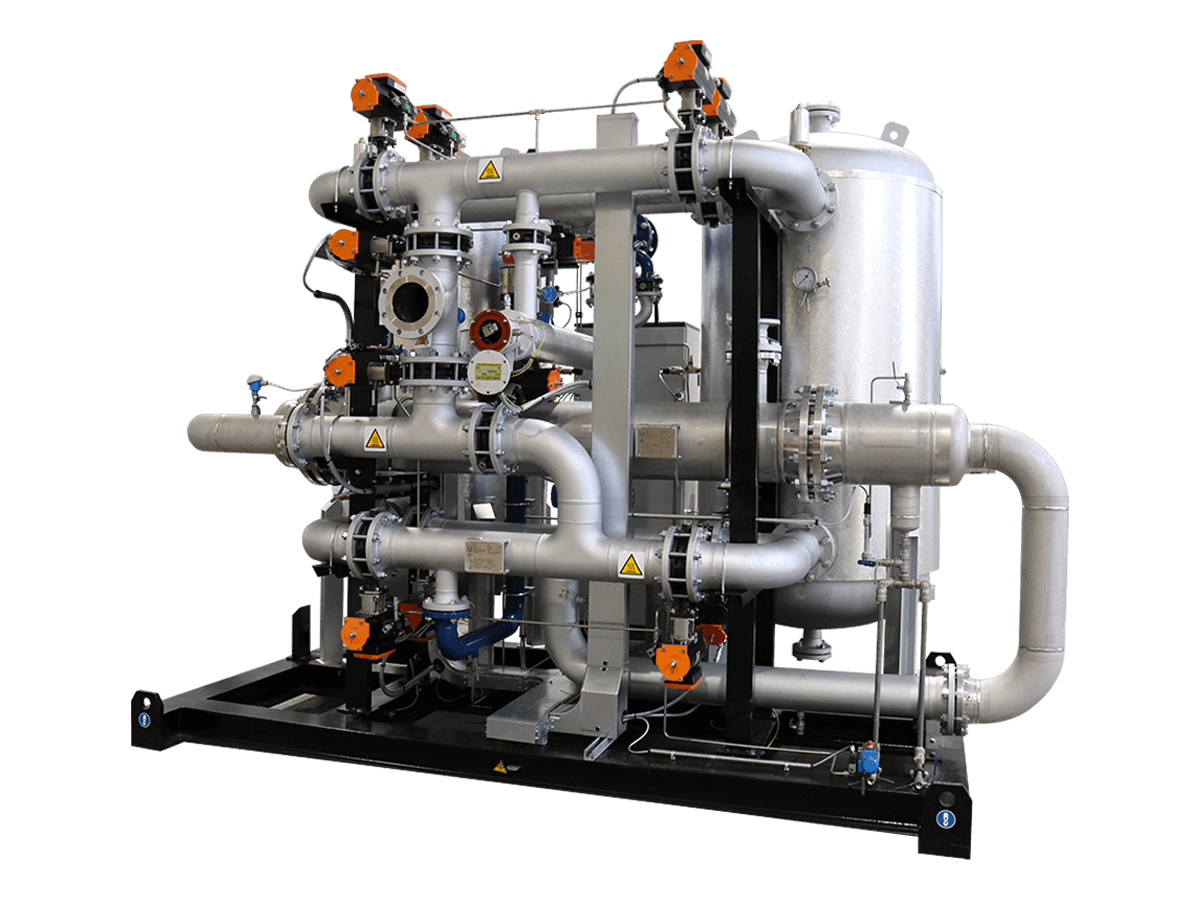

Heatless dryer

This type of air dryer, operating with pressure swing adsorption technology, is the most common type of air dryer supplied to industries. Suitable for small and medium flows air treatment, correctly sized and regulated can easily reach extreme dew point levels. Sinergia has experienced this technology since 2006, and now is able to supply fully packaged units, endowed with in-house developed unit control system (UCP), in variable configurations: Sinergia standard design, or improved for heavy duty and severe ambient installation, dangerous or explosive environmental conditions.

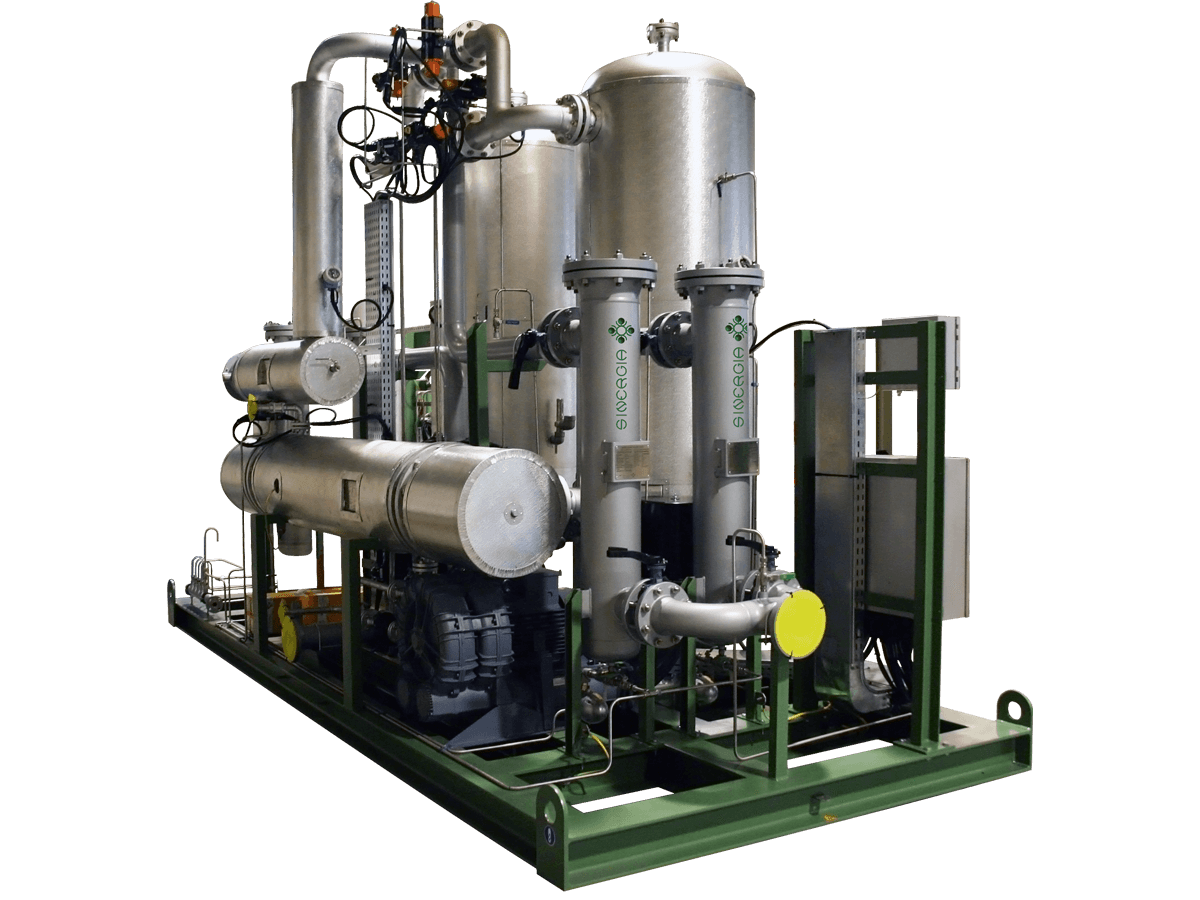

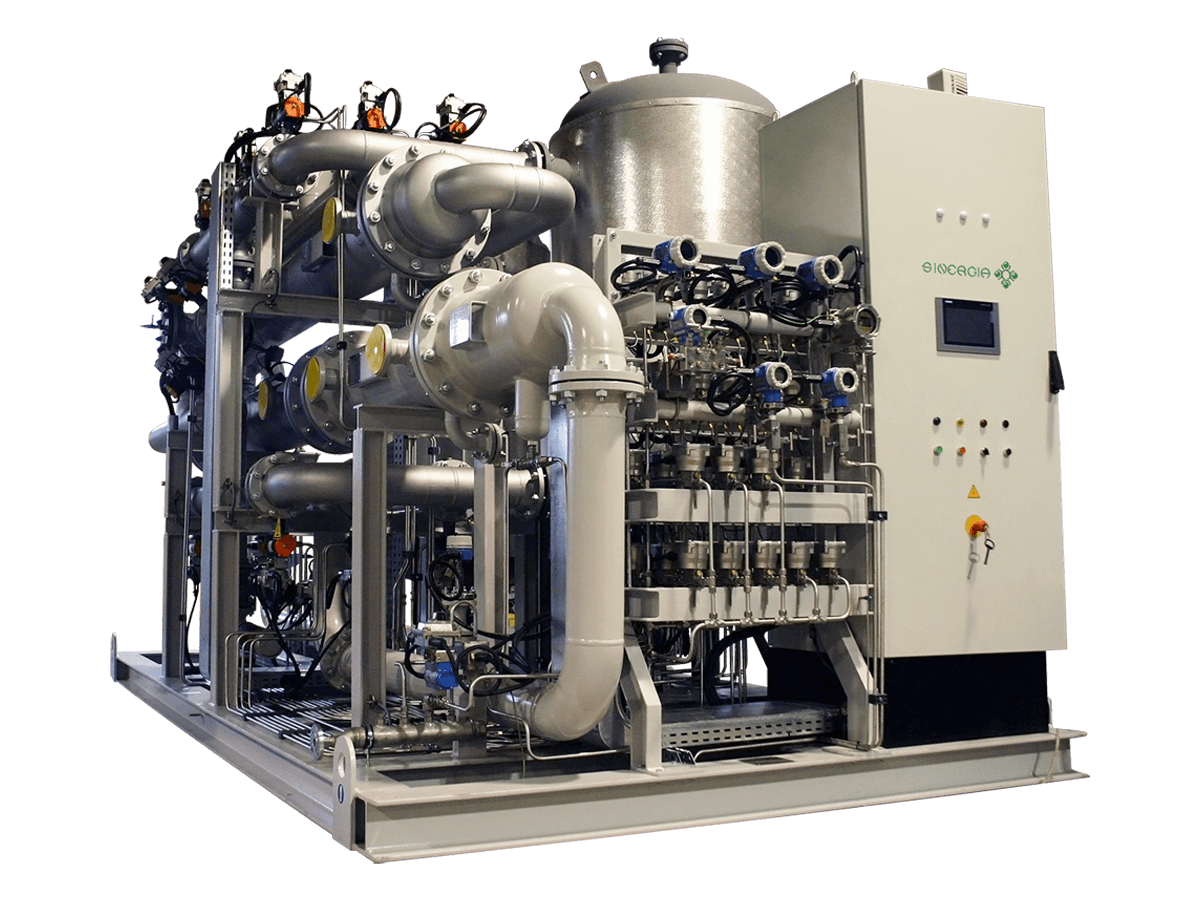

Heat dryer with blower

This air dryer is a pressure swing adsorption type, belonging to the hot regenerated family. It is commonly used for large capacities employing an external heater (electrical or steam type) to increase the performance of adsorbing material’s regeneration by reducing dry air consumption.

The additional presence of a blower increases the efficiency of the dryer by reducing further the purge air.

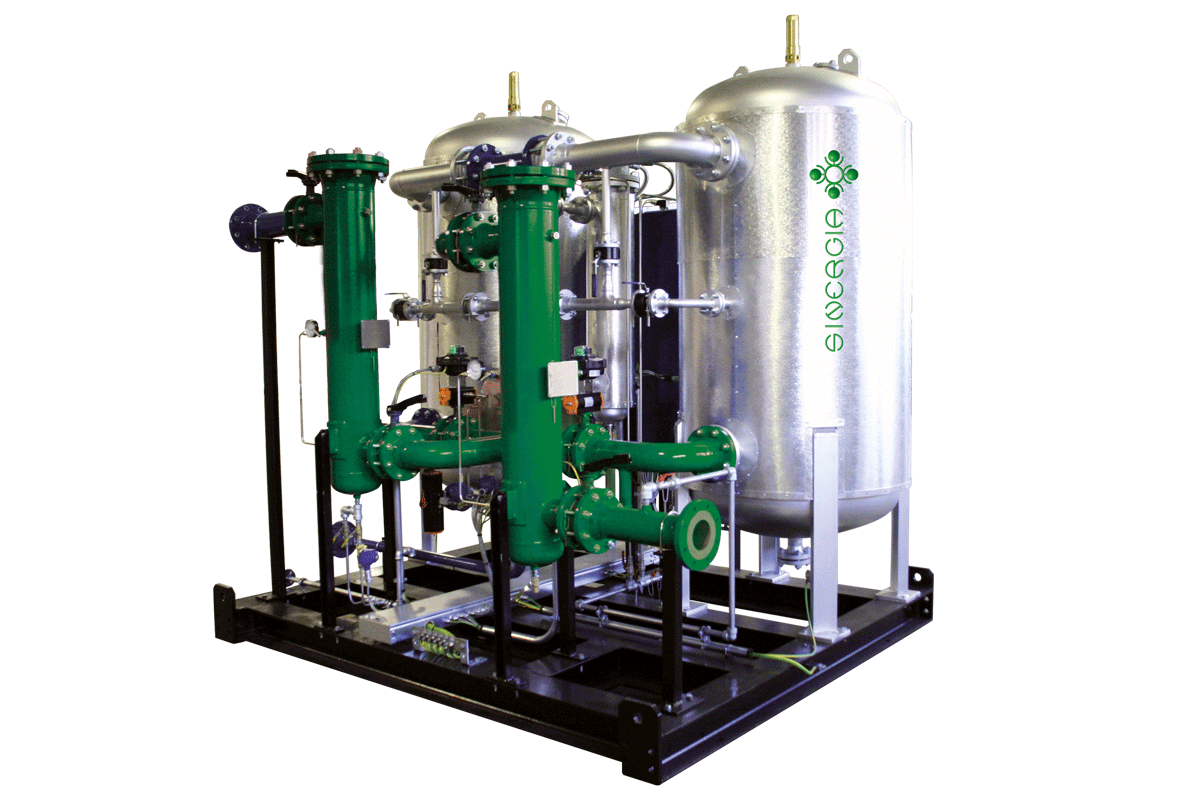

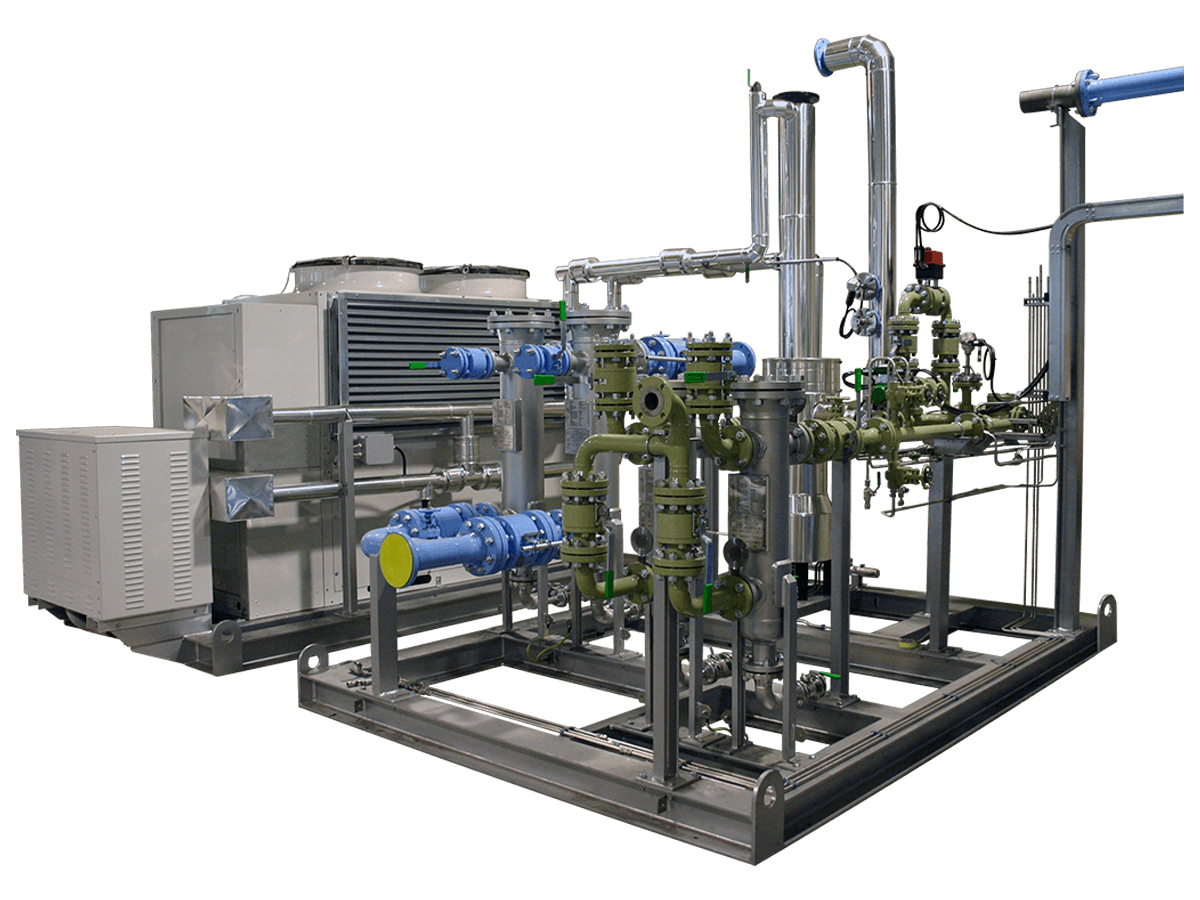

Refrigeration dryer

Sinergia designs and manufactures packaged refrigeration systems as alternative technical solution for water content reduction in compressed air. This is achieved thanks to the composition of water chiller, main heat exchanger, economizer, condensate separator, functionally integrated in order to cool down the compressed air-stream and separate the condensed water to design level (+3°C max. dew point).

The equipment composing the system can be manufactured and certified as per following calculation codes: ASME (U Stamp) - TEMA C - TEMA R.

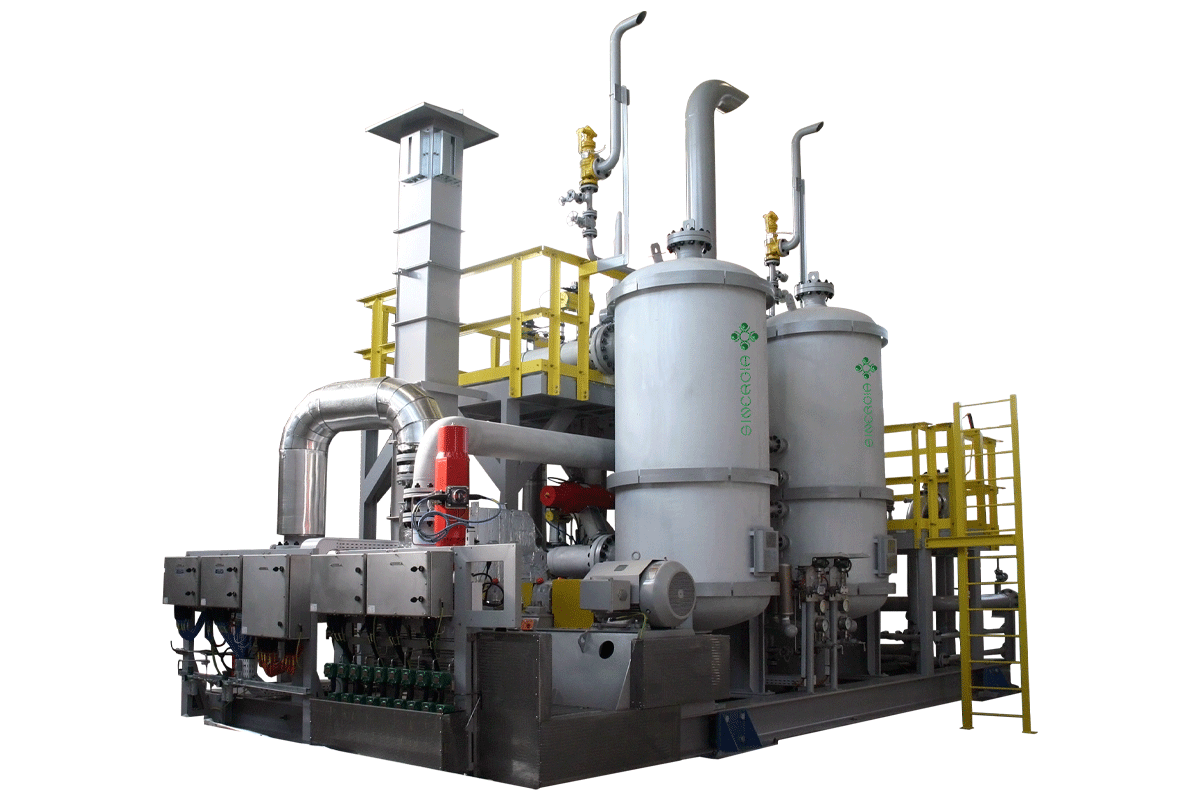

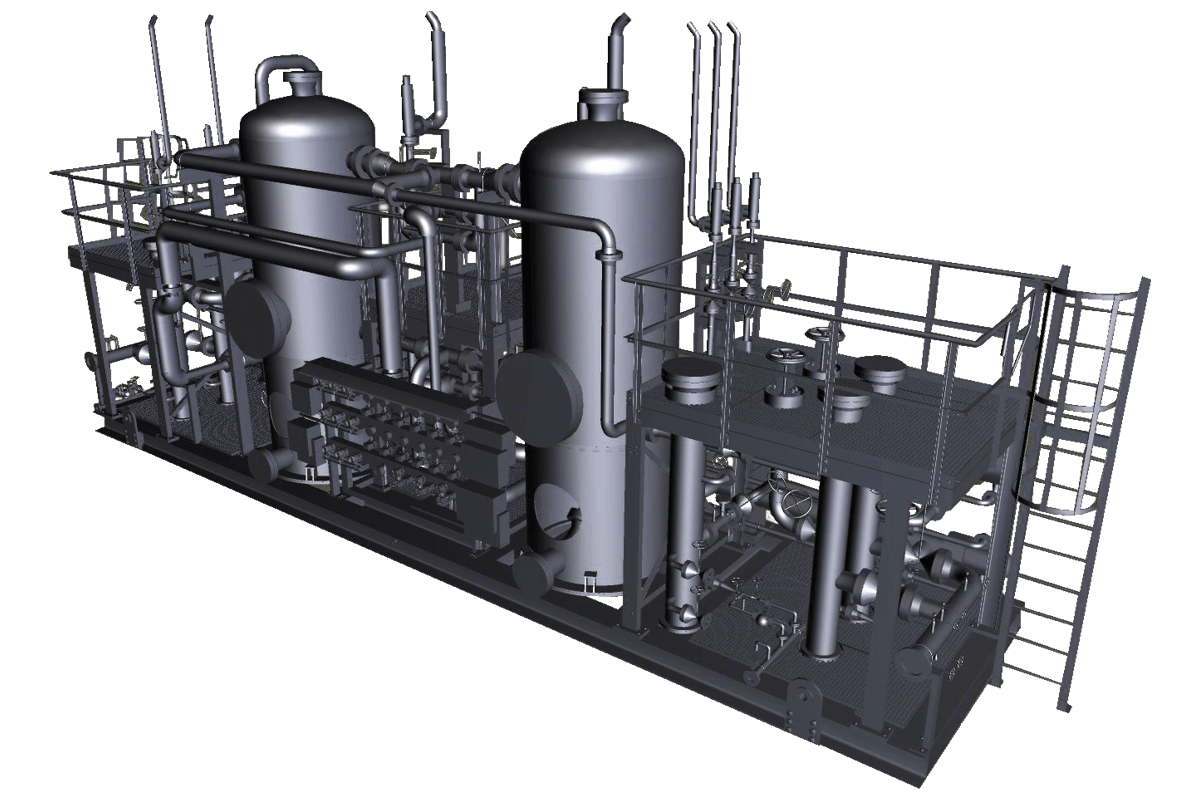

Heat of compression dryer

Adsorption dryer with hot regeneration in closed circuit version, uses the heat of compressed air-stream (aftercooler of air compressor is by-passed or excluded) in order to regenerate the adsorbing material. This type of dryer is suitable for large amount of airflow with the advantage of not requiring any external energy source and of consuming little purge air.

Heat of compression – Zero purge dryer

Adsorption dryer with hot regeneration in closed circuit version, uses the heat of compressed air-stream in order to regenerate the adsorbing material. This version of closed circuit dryer is suitable for large amount of airflow with the advantage of not requiring any purge consumption.

Blog

View all

our articles

The strength of an in-house manufactured PPU for Cryogenic Process

September 2024

The importance of an in-house pre purification unit in a Cryogenic Process

ADIPEC 2024 is coming closer

September 2024

Sinergia Stand: 11440 – Hall 11

N2 ARTIFICIAL LIFT vs ESP: Maintenance issues

August 2024

The N2 artificial lift system developed by Sinergia is not only a potential substitute for other artificial lift technologies but can be a very flexible and reliable alley (efficiency is 99% under 3 years of continuous operation) of those already installed.

PSA NITROGEN GENERATOR an efficiency improvement is possible… if you have all the skills

July 2024

Sinergia S.p.A., the leading Italian company in the engineering and manufacturing of nitrogen generators, has developed units suitable for continuous operation 24/24 h/d – 360/365 dd/y, in high ambient temperatures up to 55°C for upstream applications.

Sinergia receives the SA8000:2014 certification!

June 2024

Sinergia one of the 4000 world companies SA8000 certified.

Contact us

Contact us