Air & Nitrogen Compressors

Sinergia is internationally renowned as air compressors packager, able, thanks to agreements with main global manufacturers, to supply the most efficient compressor module, assembled in an engineered package, fully or partially customized, depending on the typical requirements of each industry sector and project specifications.

Sinergia air compressors packages can be supplied with the following features:

- High dust/sandstorm protection intake filtrating system.

- Air or water-cooled version.

- Electric (fixed or variable speed) or diesel motor driven

- Improved heating/cooling system for operation from – 40° up to + 55°C ambient temperatures.

- Suitable for dangerous or explosive environmental conditions.

- Instrumental and control system redundancies

- Containerized and mobile versions

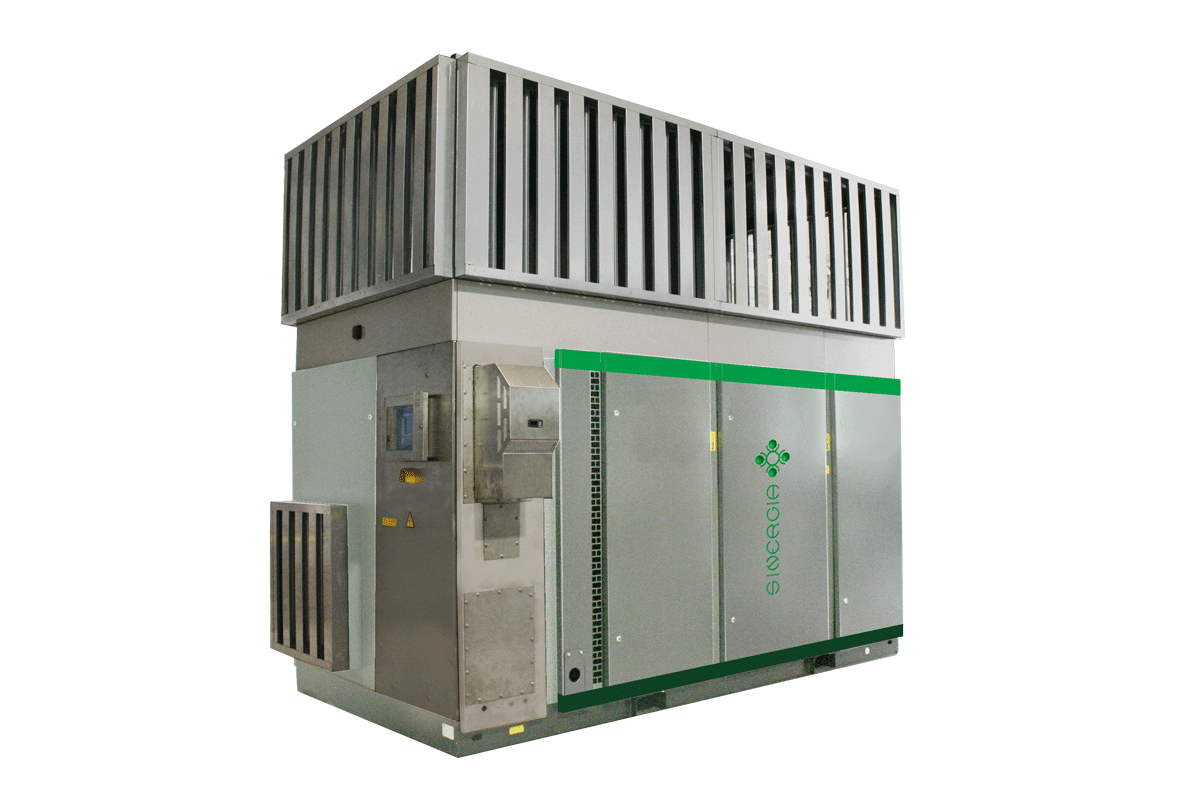

Oil free screw compressor

Oil Free Screw compressors are used for production of compressed air in a variety of processes, where the minimum presence of residual vaporized hydrocarbons (oil) may bring to critical contamination, that has to be absolutely prevented.

SINERGIA designs and manufactures high quality and innovative oil-free and oil injected air compressor packages for a wide applications' spectrum. All units are fully skidded and depending on specifications can be supplied complying with API 619 standards.

Oil injected screw compressor

Oil Injected Screw compressors are used for the production of compressed air in a variety of processes where the presence of oil vapour is not critical or can be reasonably reduced through further filtrating and absorbing treatments.

SINERGIA designs and manufactures high quality and innovative oil-free and oil injected air compressor packages for a wide applications' spectrum. All units are fully skidded and depending on specifications can be supplied complying with API 619 standards.

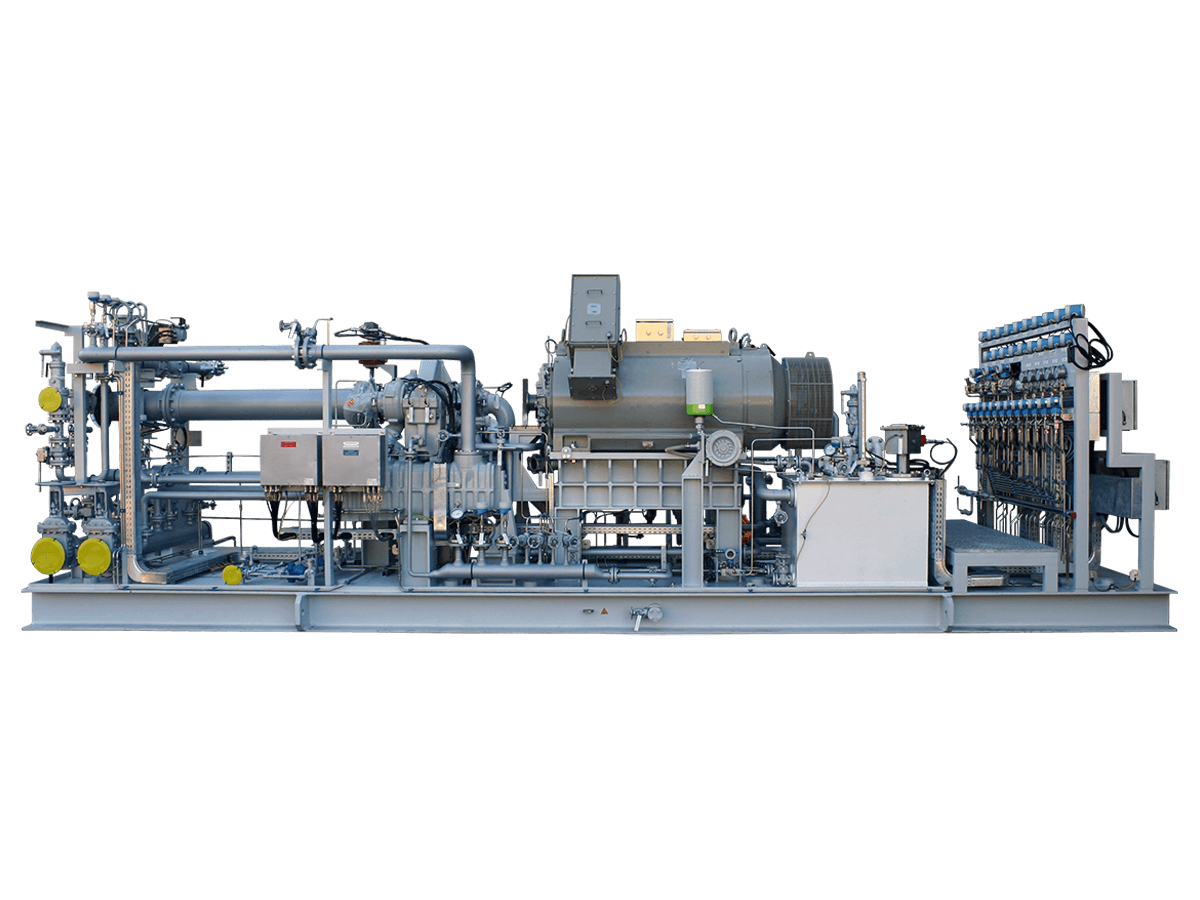

Centrifugal compressor

Centrifugal compressors are used when oil free compressed air is required in large amount and for continuous consumption applications.

SINERGIA is able to design and manufacture high efficiency packages based on centrifugal compressors. All units are fully skidded and depending on specifications can be supplied complying with API 672 standards.

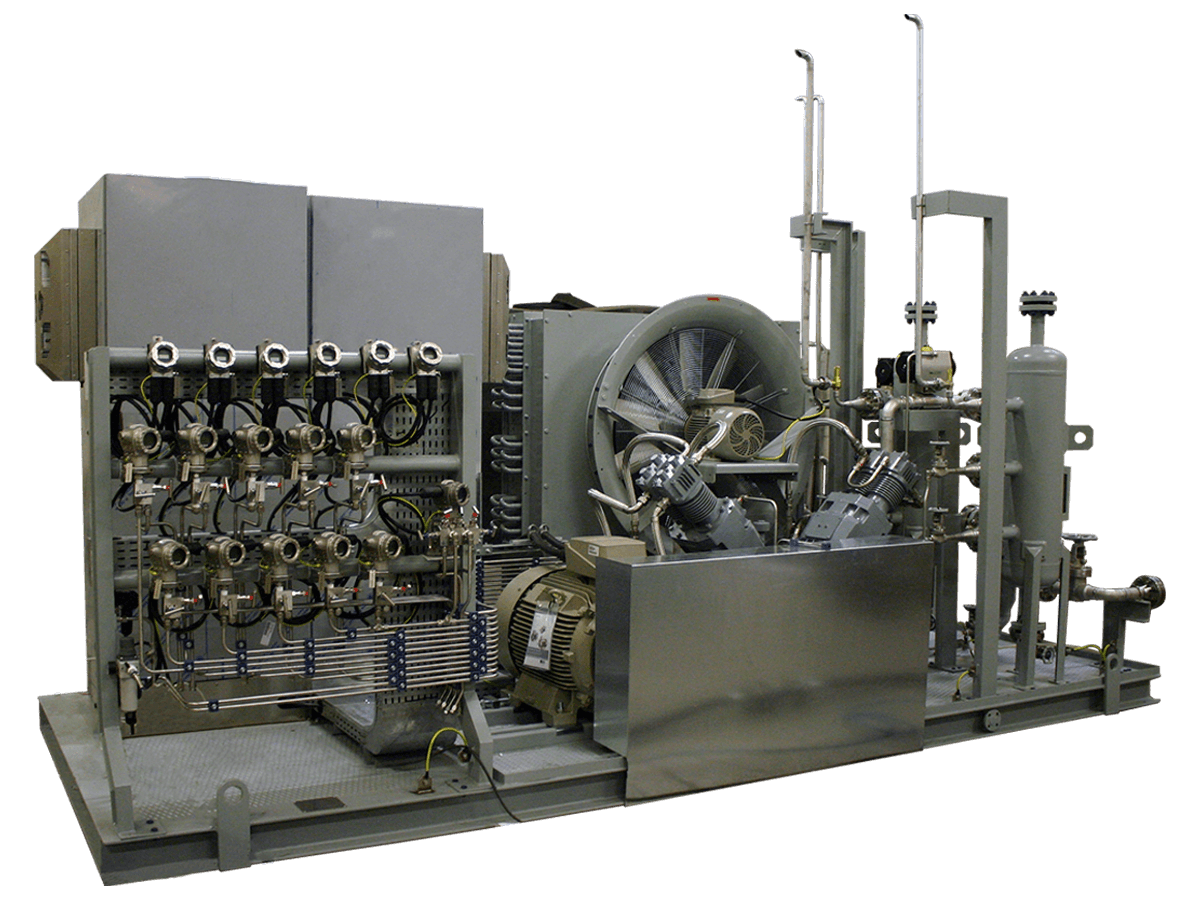

Reciprocating compressor

Reciprocating compressors are commonly used to increase the pressure of a gas.

SINERGIA designs and manufactures packaged reciprocating nitrogen compressors to be included in its nitrogen generator systems when a higher pressure is required for gaseous nitrogen storage or bottle filling. All units are fully skidded, and depending on specifications, can be supplied complying with API 618 standards.

Blog

View all

our articles

The strength of an in-house manufactured PPU for Cryogenic Process

September 2024

The importance of an in-house pre purification unit in a Cryogenic Process

ADIPEC 2024 is coming closer

September 2024

Sinergia Stand: 11440 – Hall 11

N2 ARTIFICIAL LIFT vs ESP: Maintenance issues

August 2024

The N2 artificial lift system developed by Sinergia is not only a potential substitute for other artificial lift technologies but can be a very flexible and reliable alley (efficiency is 99% under 3 years of continuous operation) of those already installed.

PSA NITROGEN GENERATOR an efficiency improvement is possible… if you have all the skills

July 2024

Sinergia S.p.A., the leading Italian company in the engineering and manufacturing of nitrogen generators, has developed units suitable for continuous operation 24/24 h/d – 360/365 dd/y, in high ambient temperatures up to 55°C for upstream applications.

Sinergia receives the SA8000:2014 certification!

June 2024

Sinergia one of the 4000 world companies SA8000 certified.

Contact us

Contact us