Chemical

Best utilities for your quality process

The chemical plant… a field of expertise

Sinergia produces compressed air and nitrogen system, essential utilities involved in many phases of production in chemical plants.

Compressed air is mainly used for general purpose as plant and instrument air. On the other hand, nitrogen, as inert gas, is commonly used in classified areas and in processes that, for safety reasons, can not accept oxygen concentration. In fact nitrogen allows to avoid the risk of explosions and combustions, and to protect raw materials and products from oxidation and contamination.

Moreover, once nitrogen is chemically combined with other elements, it forms more-reactive nitrogen compounds such as ammonia, nitrates, or nitrites. As staple element for such productions, it is usually supplied in large amounts.

Nitrogen padding of vessels, as well as blanketing and purging of reactors, pipelines, storage tanks and dusty raw material conveyors are quite common production stages in chemical plants.

Plants compliant with project specifications and environmental conditions

For the said reasons, even in variable ambient and operating conditions, utilities produced with Sinergia systems are required to mantain stable ranges in terms of temperature, dew point, pressure, concentration, and flow-rate.

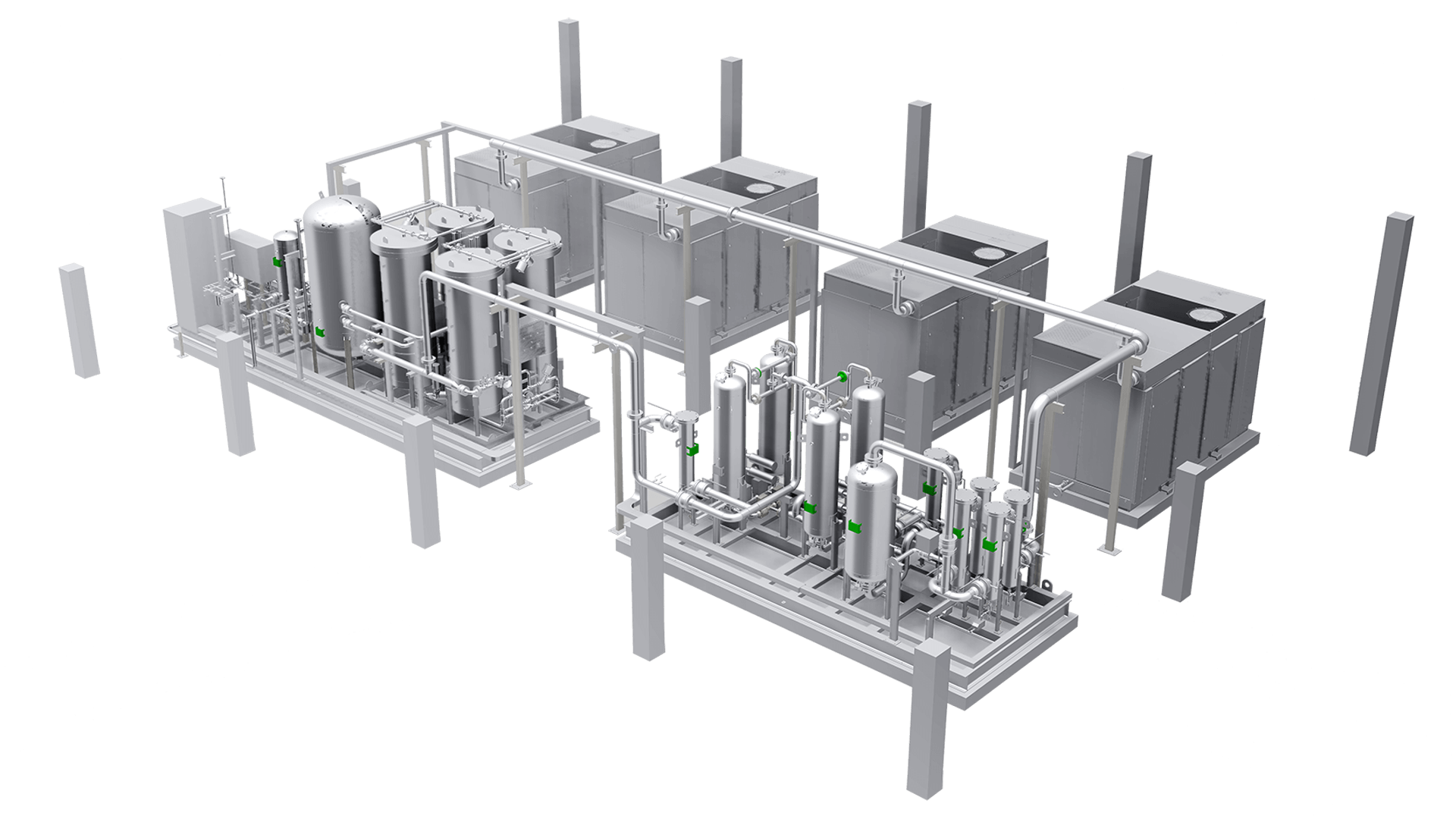

Sinergia, thanks to its know-how, guides the customer to develop integrated systems for compressed air and nitrogen. Such utilities can be delivered from one single multi-tasking unit, in many streams, having different properties, for many applications in the same chemical plant.

This goal is achievable after an accurate data analysis of the customer process, aiming to produce streams efficiently, optimizing the number of equipment, and consequently foot-print, power consumption and mantainance costs.

The analysis evaluates all complex scenarios, including variable ambient conditions, emergency situations, peaks of consumptions and priority supplies.

Sinergia confirms its advisory attitude either in the commercial bidding stage and in the operative development of the project itself.

This collaborative approach can be extended to detail engineering of all interconnecting activities between the supplied packages and main process equipment, including also all logics and the master control system, offering to our clients a turn-key solution.

Integrated system for production of plant, padding and instrument air at different pressures and dew point;

gaseous nitrogen at two different pressures and purities at 99,9%.

Installation in desertic, high temperature site.

At any latitude the most reliable technical solution

Blog

View all

our articles

Multiple utilities generation skid

February 2021

Is it possible to produce with one single plant a variety of different gaseous streams?

Our Dryer thinks outside the (heated) box

February 2021

-40°C is too cold to produce plant ad Instrument Air?

Sinergia receives the SA8000:2014 certification!

June 2024

Sinergia one of the 4000 world companies SA8000 certified.

The FIRST N2 CRYOGENIC plant start up

February 2024

Commissioning and start-up activities have been completed; the first Sinergia Air Separation Plant is definitively under operation

N2 ON SITE GENERATION for ARTIFICIAL LIFT

November 2023

Nitrogen on-site generation for artificial lift, the performing turn-key plant